Contact us

Catalogue Preface...................................... […]

Catalogue

Preface...................................................................................... 1

1、 Report Scope...................................................................... 1

2、 Report release form ...........................................................1

3、 General Manager's Speech................................................ 1

Text.......................................................................................... 3

1、 Company Profile................................................................ 3

2、 Enterprise Quality Philosophy.......................................... 3

3、 Enterprise Quality Management....................................... 5

(1) Quality management organi........................................... 5

(2) Quality Management System......................................... 6

(3) Quality and Safety Risk Management............................ 9

4、 Quality Integrity Management.......................................... 10

(1) Quality Commitment...................................................... 10

(2) Operational Management............................................... 11

(3) Marketing Management................................................. 13

5、 Fundamentals of Quality Management.............................. 13

(1) Standard management.................................................... 13

(2) Measurement management............................................ 14

(3) Certification management.............................................. 14

(4) Inspection and Detection Management......................... 15

6、 Product quality responsibility........................................... 16

(1) Product quality level....................................................... 16

(2) Product after-sales responsibility.................................. 16

(3) Corporate Social Responsibility.................................... 17

(4) Quality credit record..................................................... 19

Report Conclusion.................................................................. 20

Preface

The quality integrity report issued by the Company is prepared in accordance with relevant national quality laws and regulations, rules and relevant industrial quality standards and specifications. The quality integrity and quality management of the company in the report is a true reflection of the company's current situation. The company is responsible for the objectivity of the report content and the authenticity and scientificity of relevant statements and conclusions.

1、 Report scope

The report is organized by Hangzhou Jinhu Shoes Co., Ltd. This report describes the company's philosophy, system, measures taken and achievements in quality integrity management, quality management foundation, product quality responsibility, etc. during the period from January 1, 2021 to December 31, 2021.

2、 Report release form

The Company regularly issues a quality credit report every year. This report is published to the public in the form of paper documents on the community bulletin board. Welcome to read it and put forward valuable suggestions.

3、 Speech by the General Manager

Quality first and honest management are the basic requirements of the market economy for modern enterprises and the basis for the survival of enterprises. Hangzhou Jinhu Shoes Co., Ltd. is committed to creating a fair, transparent and open environment and corporate culture for all participants in the company's value chain. Adhering to the business management philosophy of "customer satisfaction, honest operation, people-oriented, and pursuit of excellence", we always practice the corporate mission of "providing customers with high-quality and cheap rubber shoes and rubber soles", and pursue the great vision of "becoming a well-known rubber shoes and rubber soles at home and abroad".

Jinhu attaches great importance to the construction of the quality management system, has established a perfect quality management system, and passed the quality management system certification, providing a reliable quality assurance for the company to further expand the market. The company has established a scientific and perfect quality control system, and its products meet the requirements of the group standard of "Made in Zhejiang" and are widely recognized by customers at home and abroad. In addition, the company has also established an environmental management system and an occupational health and safety management system, which have been certified.

We adhere to the quality policy of "honesty and trustworthiness, providing quality services", vigorously promote the implementation of quality integrity, and make contributions to improving the quality credit level of the entire rubber shoes and rubber soles industry.

We also sincerely hope that this report can become a window and bridge for friends from all walks of life to learn about Jinhu, and can promote our cooperation and create a better future together.

Text of the report

1、 Company Profile

Hangzhou Jinhu Shoes Co., Ltd. was established in 1996 and passed the ISO9001: 2000 international quality management system certification in 2003. The company is located in Lin'an, a national tourist city in the western suburbs of Hangzhou, Zhejiang Province, and is located in Banqiao Township Industrial Park, adjacent to Qingshan Lake, a national aquatic forest park. The transportation is very convenient. It is only an hour's drive from Xiaoshan International, Hangzhou, and the 320 National Highway of Hangzhou Huizhou Expressway passes by the factory. The company now has a factory area of more than 50 mu, a building area of more than 10000 square meters, a total investment scale of nearly 50 million yuan, more than 250 employees, four production lines and an annual production capacity of more than 1 million pairs of various rubber shoes. The main products are: fashion shoes series, Niu Bolun series, camouflage shooting series. The products are mainly exported to the United States, Britain, Canada, Norway, Denmark and other countries and regions.

The company has passed ISO9001 quality management system certification and established and operated ISO14001 environmental management system and ISO45001 occupational health and safety management system. As a backbone enterprise in the industry, it has strong development space and broad prospects.

In the face of increasingly fierce market competition, the company's leaders realized that only by establishing, implementing and improving the quality and environmental management system, paying close attention to service quality and environmental management performance, and meeting the requirements of customers and other interested parties, can the company win the market. For this reason, the company organized all employees to study GB/T 19001-2016/ISO 9001:2015, GB/T 24001-2016/ISO 14001:2015 and GB/T45001:2020/ISO45001:201:2018, and established, implemented and improved the quality and environmental management system according to this requirement, so as to improve the quality and environmental management level of the enterprise, ensure the service quality, and create greater economic and social benefits for the enterprise.

2、 Enterprise quality concept

Since its inception, the company has been committed to the control of product quality. Always uphold that product quality is the cornerstone of the survival and development of the enterprise, and is a prerequisite for occupying the market and winning customers. Quality comes from our heart. The enterprise relies on the quality concept of customers, and constantly improves and enhances the quality management level of the company. Since the company passed the quality management system certification, the company has always adhered to "quality assured, customer satisfaction." The quality policy of the Company shall be implemented in strict accordance with the requirements of relevant laws and regulations, quality management system standards, quality manual requirements, procedure documents, etc., so that the quality management system of the Company can be effectively operated, the product quality can be effectively guaranteed and continuously improved, and the quality objectives of the Company can be basically achieved. In order to fundamentally strengthen and improve the quality management and improve the company's operating quality, the company took the introduction of the excellent performance model as an opportunity to promote total quality management, use project management, and constantly seek opportunities for improvement in quality management through internal audit, self-evaluation, second party audit, third party audit or evaluation, quality month and other activities to gradually achieve excellent performance.

1) Quality, environment, occupational health and safety policy:

Quality assurance and customer satisfaction; Integrity and law-abiding, up to standard emission;

People oriented, safe and healthy; Continuous development and striving for first-class.

2) Policy connotation:

The company provides an environment-friendly and safe production environment, always adheres to safety first, produces and sells green environment-friendly products, reduces waste emissions, pays attention to fuel, electricity and water conservation, actively applies new processes, new technologies and new equipment that save energy and consumption, optimizes production, optimizes resource allocation, and realizes production increase and energy conservation; The company starts from the details, covers the management to every corner, achieves that everyone has a post and responsibility, strengthens the refined management, and strives to carry out all-round governance to the management efficiency, optimize the operation process, and constantly promote the comprehensive, coordinated and sustainable development of the company.

3) Quality objectives:

① One time acceptance rate of finished products ≥ 98%;

② Customer satisfaction rate ≥ 90%;

Since the establishment of the company, the company has never had any major product quality complaints, and the qualification rate has reached 100% in the sampling inspection by the quality and technical supervision departments at all levels over the years.

3、 Enterprise quality management

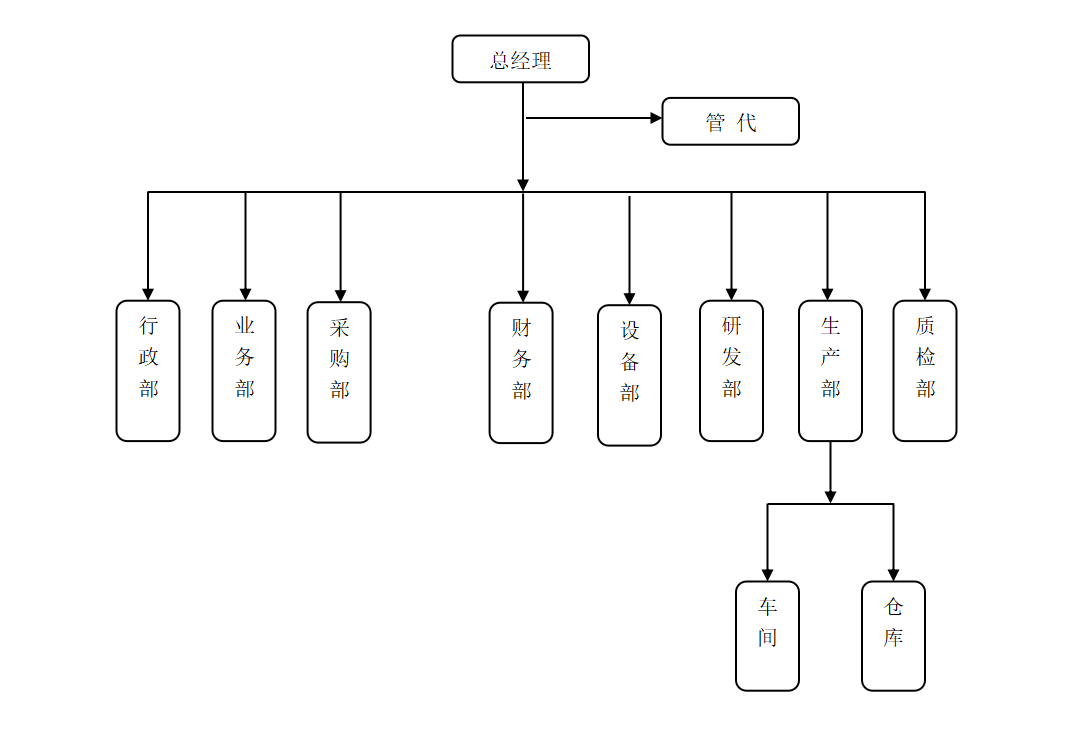

(1) Quality management organization

A product is the output or result of a process. Product quality is determined by process quality, and process quality is determined by system quality. In order to ensure the quality of systems, processes and products, the company has identified the required processes and their interface relationships and established the quality management framework of the company according to the requirements of the quality management system standards, using the management system methods and process methods.

Figure 1 Organization Chart of the Company's Quality Management System

The Company's Technology and Quality Control Department is responsible for the quality and safety of products and services, and performs the following duties:

① Participate in the formulation, review and determination of quality strategy;

② Convey to the organization the importance of meeting customer requirements and legal and regulatory requirements;

③ Formulate quality policy;

④ Ensure the establishment of quality objectives;

⑤ Conduct management review;

⑥ Ensure the availability of resources;

⑦ Organize and participate in the monthly quality meeting;

⑧ Organize and participate in major product quality review and quality improvement activities;

⑨ Organize and participate in quality commendation activities;

⑩ Establish a clear quality accident accountability system and quality safety traceability system.

(2) Quality management system

1) Quality Management System Policies and Objectives

The quality management system established and implemented by our company has passed the ISO 9001 quality management system certification, and has formulated "safety, environmental protection, consumption reduction and efficiency increase; responsible and meticulous management" Management policy; And 1) the one-time acceptance rate of finished products ≥ 98%; 2) Customer satisfaction rate ≥ 90% is the quality target. In order to continuously improve the company's quality management system, the company makes plans every year to implement internal audit of the quality management system and find opportunities for improvement. At the same time, make full use of the opportunities of two party audit and three party audit to improve the effectiveness of the quality management system.

The company also introduced the excellent performance management mode and implemented the total quality management, so that the company's quality management system can be aligned from continuous improvement to the pursuit of excellence. An integrated total quality management system has been established with the company's strategy as the core and the excellent performance model of GB/T 19580 as the framework. Meet the requirements of customers, employees, suppliers, society and partners, and establish corresponding strategic plans and quality objectives at all levels of the company. Based on the company's performance appraisal system, the quality appraisal KPI and quality accountability system have been established.

2) Quality education

In the process of system operation, the company, based on the PDCA system method, uses various scientific and effective tools to measure, analyze and improve the effectiveness of the quality management system and the performance of each department and level, and adopts benchmarking and learning methods to constantly revise individual work ideas and consciousness to ensure the realization of the overall goals of individuals and the company. The company establishes a trainer system internally, and carries out various education and training work according to the specific situation of the company; Externally, actively communicate with customers, government functional departments and various training institutions, and invite experts to conduct special training for the company's employees in due time. The company regularly carries out targeted quality education for employees at all levels in combination with the system operation and actual quality performance, and conducts special management on quality control points to ensure the consistency of product quality in the manufacturing process.

3) Quality regulations and responsibility system

By collecting laws and regulations and other standards and requirements, the company formulates internal relevant standards to make products meet the requirements of national laws and regulations and national and industrial standards, and practices social responsibility in terms of product technology.

|

category |

content |

|

Corporate governance |

Company Law, Accounting Law, Enterprise Income Tax Law, Individual Income Tax Law, Implementation Regulations of Enterprise Income Tax Law, Business Tax Regulations of the People's Republic of China, Product Quality Law, Company Registration Rules, Commodity Inspection Law, Work Safety Law, etc |

|

Safeguarding employee rights and social responsibilities |

Labor Law, Trade Union Law, Work Safety Law, Occupational Disease Prevention Law, Provisions on Prohibition of Child Labor, Regulations on Work Injury Insurance, etc |

|

Applicable environmental, health and safety regulations |

Environmental Protection Law of the People's Republic of China, Energy Conservation Law of the People's Republic of China, Labor Contract Law, Work Safety Law, Occupational Disease Prevention Law, GB/T 24001, GB/T 45001 |

|

Product technical standards |

T/ZZB 0589-2018 rubber sole |

Table 1 Quality Standards and Other Relevant Laws Followed by the Company

The company has formulated the Control Procedure for Nonconformities, Corrective and Preventive Measures to strictly control the nonconforming products. The company has formulated inspection standards, and the products can only enter the next process or leave the factory after passing the self inspection and special inspection. Any nonconforming product shall have clear requirements for identification, record, isolation and treatment. At the same time, all nonconformities are recorded in detail, and the responsible unit shall formulate corrective measures and make rectification after statistical analysis by specially assigned personnel. The problem items can be closed only after the corrective measures are evaluated to be effective.

In addition, the Company shall be responsible for and educate the quality problems, and emphasize standardization in daily development and production operations. Through continuous improvement and other activities and quality functions, the PDCA cycle shall be fully applied to achieve continuous improvement and excellence.

(3) Quality safety risk management

All products and processes of the Company shall be designed and developed in accordance with the Control Procedure for Design and Development, potential failure mode and consequence analysis shall be carried out for product characteristics and process characteristics, and necessary measures shall be taken for links with high risk sequence to reduce risks. Prepare control plans, operation instructions and other documents according to procedure requirements, and conduct risk analysis on each product requirement and process link. Each link shall be strictly controlled and checked to ensure that each production process meets relevant requirements and the final product quality is qualified. In the whole production process, set up inspection stations, such as incoming inspection, process inspection, and final inspection, to check at all levels. And carry out quality management system audit, process audit, product audit and other work as required.

In terms of quality management and control, the company has established Emergency Preparedness and Response Control Procedures to prevent quality and safety risks. The company has developed a quality and safety emergency plan and established an emergency leading group with the general manager as the leader. The responsibilities of the emergency response leading group and relevant departments were clarified.

4、 Quality integrity management

(1) Quality commitment

1) Honesty and law-abiding

For a long time, the senior leaders of the company, starting from the core values of the enterprise, have attached great importance to the cultivation of the enterprise's moral culture in the process of implementing the enterprise culture construction, and strive to create a good atmosphere of advocating moral cultivation, which is practiced by the senior leaders of the enterprise and actively participated by all employees. The Company has established and improved its management system in accordance with the Company Law, Accounting Law, Labor Law and other national laws and regulations; The senior managers of the Company are strict in management and set an example. As a model and benchmark for observing disciplines and laws, they insist on operating in accordance with the law in their business activities. Since the establishment of the Company, none of the senior managers of the Company has violated laws and regulations.

When carrying out projects and signing contracts, the company implements a risk control linkage mechanism controlled by legal consultants and leaders, and strives to prevent and control legal risks from the source. At the same time, the company has built a library, training room, and bulletin board. By studying the Safety Production Law, Trade Union Law, and other laws and regulations closely related to enterprises and employees, the company has greatly improved the awareness of cadres and employees about laws and regulations, The awareness of honest operation and market rules of enterprise management personnel has been enhanced. Knowing and abiding by the law in work and life has become a conscious code of conduct for employees.

The Company pays taxes and fees according to law, has a sound financial system and standardized accounts, entrusts the tax bureau and the audit bureau to carry out final settlement and audit every year, actively cooperates with the national and local taxes for tax inspection, and at the same time, the Company abides by market rules and has a good credit record.

2) Meet customer needs

The company attaches great importance to technology research and development, accurately understands customer needs through industry associations, product fairs, technical exchanges, daily communication and other ways, promotes technology progress with upstream strategic suppliers, downstream strategic customers, and downstream strategic customers of customers, improves product quality, and provides customers with high-level products at a high cost performance ratio. The company strengthened the investment in R&D, focused on customer needs, actively listened to customers' opinions and suggestions on functions, quality, costs, etc., and carried out product improvement and innovation activities to meet customers' needs for products and delivery dates. In terms of product quality, the company strictly implements the quality management system, and ensures product quality and safety through technical research, quality improvement, QC team and other activities.

3) Make the following commitments to the "Made in Zhejiang" certified products:

① Users should use and store the frying pan correctly according to the instructions. The company guarantees that the frying pan can be used normally within one year after purchase. If the stickiness disappears or the normal use is affected within the specified time, the company will repair or replace it for the user free of charge.

(2) Operation management

1) Product design integrity management

The company's product design and R&D are strictly in accordance with the Design and Development Control Procedure, and the whole process related to R&D is controlled from the R&D project initiation, various activity records, R&D process summary, and management evaluation. Respecting others' knowledge and participating in the practice of protecting intellectual property rights is one of the important contents of our design and development work.

2) Integrity management of raw materials or parts procurement

The enterprise formulates the Procurement Control Procedure to classify and manage materials according to the risk degree of materials to product quality. For material suppliers, in addition to meeting the statutory qualifications, they must also conduct regular on-site inspections. Whether on-site review is required depends on the quality of materials provided by the supplier. And sign the Environmental Protection and Safety Proposal of Interested Parties with suppliers, and establish quality files for material suppliers. Each batch of purchased raw materials shall be inspected. Raw materials that fail to meet the specified standards shall not be put into storage for use.

3) Integrity management in production process

The production department of the company is specifically responsible for the production management of various varieties and on-site process management. Various production management systems, work standards, post operating procedures and various process procedures, management procedures and standard operating procedures have been formulated and gradually improved. The workshop centralized training and pre shift and post shift meetings shall be used to conduct comprehensive post skills training for operators at all posts, and various methods shall be used for supervision and assessment, so as to enhance the quality awareness of employees and improve the operation level. During the production process, management personnel at all levels shall strictly perform their management responsibilities, check in time, correct errors in time, and ensure the stability of the production order.

Recheck the raw materials, auxiliary materials and packaging materials required for production before feeding, control the quality of intermediate products and finished products, strictly implement the "three non principles" of "no production of nonconforming products, no acceptance of nonconforming products, and no circulation of nonconforming products", set quality control points for key processes, urge employees to do well in self inspection and mutual inspection, implement monitoring and verification procedures, strictly manage records, and achieve unified receipt, distribution and verification. Material balance shall be carried out for each production step to ensure that the input of materials and the output quantity of products are consistent with the process requirements, and that there is no potential quality hazard and that the requirements of accounts, materials and cards are consistent.

Production records shall be reviewed, printed and kept by the Production Department. Employees must fill in production records in time as required to ensure clear handwriting, true content, complete data, and signed by operators and reviewers for confirmation. After the production is completed, the team leader shall summarize and review the records and submit them to the Production Department in a timely manner. After the review, they shall be filed according to the batch number and managed by a specially assigned person.

(3) Marketing Management

The company conducts in-depth understanding of customers and markets through scientific market research. In addition to collecting market intelligence by the sales department, the company also fully understands the needs, expectations and preferences of customers and the market by means of regular visits, customer satisfaction surveys, regular marketing seminars, etc., so as to position the company's products, classify customers and subdivide the market. In addition, the company also conducts in-depth research on some markets (such as Bangladesh, Vietnam and other regions) to lay a foundation for exploring and cultivating potential markets.

The company has established the service concept of "customer demand orientation", requiring business personnel to be warm and considerate to any customer, whether he places an order or not, and try to meet all their reasonable needs. Relevant procedures such as Customer Related Process and Customer Satisfaction Measurement Control Procedure have been formulated to increase the skills and quality of business personnel in all aspects and improve the customer turnover rate.

Through continuous improvement of technical innovation, product quality, marketing mode, customer service, emotional cultivation, cultural exchange and other ways, the company keeps contacting and following up with potential customers, including competitors' customers, analyzes the needs and preferences of potential customers, and conducts point-to-point improvement and innovation for the company's products. From small to large, from small to large, gradually win competitors' customers and stabilize the potential customer market, Continue to improve customer effectiveness and market share.

5、 Fundamentals of Quality Management

(1) Standard management

The company applies enterprise standardization throughout the whole production process, and has formulated relevant standards from the purchase of raw and auxiliary materials, packaging materials, semi-finished products, finished product inspection and other aspects. Thus, the whole production process from raw and auxiliary materials entering the factory to finished products leaving the factory is under standardized and standardized management, laying a good foundation for stabilizing product quality and improving enterprise management level.

(2) Measurement management

The company strictly implements the Metrology Law of the People's Republic of China and other documents and regulations, and has established a set of management documents and control methods from raw material procurement, process management, production equipment, inspection equipment, process inspection, finished product inspection and other links. The full-time and part-time measuring personnel are responsible for the management, allocation and regular calibration of the company's measuring equipment in use, and pay attention to the professional training of measuring management personnel, which provides a strong guarantee for the standardization of the company's measurement management.

In order to ensure the product quality, the production process of the product shall be strictly controlled, and the measurement management of raw and auxiliary materials in the production process shall be strengthened to ensure the normal operation of measuring equipment and the accuracy of measurement. The purchase, warehousing and ex warehouse of measuring instruments shall be carried out in strict accordance with the approval plan and management procedures. The warehouse shall have a specially assigned person to keep the measuring instruments, establish the account and registration procedures. The receiving and ex warehouse of measuring instruments must pass the verification, and the measuring instruments can be put into use only with the verification certificate; The measuring instruments in use shall be verified in strict accordance with the cycle, the on-site inspection and supervision shall be strengthened, the use situation shall be mastered, and the problems found shall be handled in a timely manner; Put forward rectification suggestions for the departments with problems, and take active and effective measures to rectify, laying a solid measurement foundation for the production of high-quality products.

(3) Certification management

At present, the company has passed the ISO 9001 quality management system certification, established the ISO 14001 environmental management system and the ISO 45001 occupational health and safety management system, and carried out the "Made in Zhejiang" brand certification process. The company operates the improvement system in strict accordance with international standards, so that the quality of the enterprise's products can be effectively guaranteed, so that the enterprise's quality policy can be successfully implemented. Since the establishment of the factory, the company has never had any major quality complaints, and the qualification rate has reached 100% in the sampling inspection of quality R&D departments at all levels over the years.

(4) Inspection and detection management

The company ensures that the raw and auxiliary materials provided by the General Management Department and the Production Department meet the specified requirements through the inspection of incoming goods. The Technology and Quality Control Department is responsible for preparing the incoming inspection procedures and inspecting the incoming raw and auxiliary materials; The General Management Department and the Production Department are responsible for the disposal of unqualified raw and auxiliary materials; The General Management Department is responsible for counting and receiving the purchase quantity and name of raw and auxiliary materials.

In order to ensure that all products can enter the next process only after passing the specified inspection in the production process, the company formulates the Product Monitoring and Measurement Control Procedure and the Nonconforming Product Control Procedure to carry out strict process inspection. The Technology and Quality Control Department is responsible for formulating process and final inspection and test procedures, establishing inspection points for final inspection, and organizing process inspection; The quality inspector is responsible for the inspection of inspection points, semi-finished products and finished products; Each production operator is responsible for self inspection and mutual inspection.

|

Serial No |

name |

Specification and model |

quantity |

supplier |

|

1 |

Vulcanizer |

R1-1-7028 |

1 set |

Jiangdu Tougheng Machinery Factory |

|

2 |

Static resistance tester |

GT-70S8-EN |

1 set |

High speed Railway Testing Instrument Co., Ltd |

|

3 |

Tensile machine |

DL-B2500N |

1 set |

Jiangsu Xinzhenwei Testing Machinery Factory |

|

4 |

Impact testing machine |

GT-7037-HE |

1 set |

High speed Railway Testing Instrument Co., Ltd |

|

5 |

Wear resistance tester |

XD-331MBS |

1 set |

High speed Railway Testing Instrument Co., Ltd |

|

6 |

Folding resistance tester |

GT-7011-SA |

1 set |

High speed Railway Testing Instrument Co., Ltd |

|

7 |

Labor resistance and cracking tester |

WPL-100 |

1 set |

Jiangdu Xinzhenwei Testing Machinery Factory |

|

8 |

Anti-skid tester |

GW-026A |

1 set |

Juwei Instrument Co., Ltd |

Table 2 List of main testing equipment of the company

6、 Product quality responsibility

(1) Product quality level

In the past three years, the company's main performance indicators have made great progress. In 2021, the company's sales revenue will reach 47.51 million yuan, with a profit of 3.42 million yuan. Under the condition of fierce competition in the whole rubber shoes and rubber soles industry, the company has further expanded the market share of rubber shoes and rubber soles by changing its business concept, improving its R&D ability, strengthening its production capacity, and consolidating its management foundation, while comprehensively improving its management level and product quality in the business process.

(2) Product after-sales responsibility

The company establishes and implements customer complaint handling procedures to ensure timely and effective handling of customer complaints. Customer complaints shall be handled by full-time personnel. Each complaint shall be closely monitored. Based on the difference in the type and degree of customer complaints, the customer shall be the center and pay attention to collecting and solving customer feedback, and necessary corrective/preventive measures shall be taken to prevent similar problems from recurring. Follow up the complaint handling process by telephone return visit to understand customer satisfaction.

At the same time, the Company's Technology and Quality Control Department regularly monitors the customer complaint information, collects and analyzes the problems that occur repeatedly in the market and affect customer satisfaction and product commissioning, and forms a report. Regularly organize internal departments to hold product quality meetings to tackle and improve major product quality problems, eliminate quality risks and improve product quality satisfaction.

Jinhu has a perfect after-sales service guarantee system, and Jinhu has a perfect after-sales service guarantee system. Within 10 months from the date of shipment, samples of each batch of products are kept to ensure that the products are traceable. During the product warranty period, if there is a product quality problem, replace the corresponding number of products free of charge and compensate for the corresponding losses; During the product warranty period, if the product cannot be used normally due to improper use or other non quality problems, the company will organize or assist to solve the problem according to the user's needs.

After the products leave the factory, there are special after-sales service personnel to follow up. If the customer has problems during the use of the products, the company will respond within 8 hours after receiving the customer's phone call or other ways to obtain user feedback, and provide the customer with solutions within 24 hours.

(3) Corporate Social Responsibility

The Company actively performs its public responsibilities, civic obligations and abides by the code of ethics while developing its business continuously. In terms of public responsibility, the company has taken environmental protection, occupational health and safety of employees and energy consumption reduction as the focus of its work, actively innovated and continuously improved, and achieved remarkable results; In terms of moral behavior, the company has put forward the talent concept of "training and growth", and taken into account the interests of customers, company employees, the government and other relevant parties; In terms of public welfare support, senior leaders take the lead in setting an example, and employees actively participate in and actively repay the society.

1) Public responsibility

The company strives for the harmonious development of the enterprise and the environment, and actively invests in advanced equipment and technology with reasonable profits and economic benefits. Through the risk identification of the harmful impact that the company may cause to the society in the enterprise operation, and in strict accordance with various relevant laws and regulations, various effective governance measures are taken to make it meet the requirements of laws and regulations and safeguard the social public interests.

The company's products, production and operation processes have little adverse impact on environmental pollution and social risks, but the company still attaches great importance to environmental impact control, strictly implements the relevant national laws and regulations, establishes and implements the environmental management system and occupational health and safety management system, develops and implements the Emergency Preparedness and Response Structure List, Emergency Plan and other systems and management methods, and organizes the signing of the letter of responsibility for safety management objectives every year; Establish safety early warning mechanism and safety accident emergency handling mechanism; Carry out fire drill and emergency muster drill regularly every year to achieve the environmental, safety and health objectives; At the same time, the company has formulated energy conservation management system and resource recycling system to recycle available resources. The measurement indicators, methods and control processes of the company's environment, safety and energy consumption are shown in the table below.

The Company analyzes and evaluates the Company's problems in quality management, environmental protection, energy consumption, comprehensive utilization of resources, health and safety through annual internal audit, second party audit, third-party supervision and audit, and takes measures to implement improvement.

2) Moral behavior

The moral behavior of the company is mainly shown as follows: it is mainly responsible for senior leaders, middle leaders and employees within the enterprise; Mainly responsible for suppliers among enterprises; It is mainly responsible for customers, shareholders, government and society outside the enterprise.

Inside the enterprise: democratic evaluation is conducted once a year for senior leaders, mainly focusing on political thought, leadership art, business and other aspects; For middle-level leaders, several regulations on honest employment of leading cadres shall be formulated to improve the ethics and management level of middle-level leaders. There are various administrative management systems and other binding norms for the company's employees.

Between enterprises: the company has established a good partnership with suppliers, and has regular meetings and exchanges. In the daily procurement of raw and auxiliary materials, the General Procurement Management Department shall operate in strict accordance with the Contract Law and the Procurement Control Procedure to minimize the contract default rate and claim amount.

Outside the enterprise: for customers, ensure the quality and abide by the contract. The company's products mainly implement three standards in terms of quality, one is the same as the national quality laws and regulations, one is the quality standard in the industry, and the other is the quality requirements standard of the enterprise itself. Relatively speaking, because of the company's leading position in the industry, its own standards are often higher than the national or industrial standards, and the product quality is widely praised. At the same time, in terms of fulfilling marketing contracts, the company has always operated in accordance with the "Contract Law", and has good cooperation with customers, no matter big or small. For the government: pay taxes according to law, be honest and self-discipline. Paying taxes according to law is the basic moral bottom line of an enterprise, and also an important guarantee for realizing the benign development of the economy and society. As a law-abiding enterprise, the Company shall pay taxes according to law.

3) Public welfare support

The company emphasizes the social responsibility of the enterprise and sincerely returns to the society. The general manager attaches great importance to public welfare support, vigorously advocates and sets an example. The company's leaders will continue to develop public welfare with the continuous development of the enterprise. The company cooperates with the enterprise's strategy to plan the cost and direction of public welfare support every year.

| Serial Serial Serial No | content | Relevant units | Date of donation |

| 1 | Charitable donation 6000 yuan | Lin'an Charity Federation | 2019.5 |

| 2 | Donation of 20000 yuan | Lin'an Chengnan Primary School | 2019.9 |

| 3 | Charitable donation of 10000 yuan | Lin'an Charity Federation | 2020.2 |

| 4 | Donate 3000 yuan to the disaster area | Organization Department of the CPC Central Committee& Organization Department of the CPC Hangzhou Municipal Committee |

2020.8 |

| 5 | Charitable donation of 15000 yuan | Lin'an Chamber of Commerce | 2020.10 |

| 6 | Charitable donation 20000 yuan | Lin'an Red Cross Society | 2021.7 |

Table 4 Public Welfare Support Achievements of the Company in Recent Three Years

(4) Quality credit record

Since the establishment of the factory, the company has never had any major quality complaints, and the qualification rate has reached 100% in the sampling inspection of quality R&D departments at all levels over the years.

Conclusion

The construction of quality and integrity is the common responsibility of the whole society, which requires everyone's joint efforts. Jinhu has always adhered to the corporate spirit of "honesty first, pragmatic and enterprising, brave in development, and win-win cooperation" and the management policies of "compliance with laws, quality first, pollution prevention, energy saving and consumption reduction, creation of excellence, and pursuit of perfection" and "safety first, prevention first, hidden danger management, and continuous improvement", to provide customers with good products and technical support, sound after-sales service, and to build well-known rubber shoes at home and abroad Rubber sole. Improve the quality and integrity construction level of the enterprise, establish a good image of the Jinhu brand, and make our due contribution to the healthy, orderly, sound and rapid development of the industry!